Browse Our Lean Manufacturing Consulting Services

What We Offer

Lean System Integrators, Inc. gives an analysis of your operation, including a written report with the following:

- Critique of the operation

- Identification of opportunities for improvement

- Specific suggestions as to how to address those opportunities

- A PowerPoint presentation to discuss the methodology and findings, and recommendations

- Plant layout analysis and development

- Workshops on the various lean tools

Supply Chain Management

- Analysis of Supply Chain

- Logistics

- Production Planning

- Purchasing

- Warehouse Management

Business Coaching

- Strategic Business Planning Development

- Goal Setting and Tracking

- Manufacturing Financial Analysis

- Organizational Structure

- Product Line Retention Decisions

- Continuous Improvement

- Cash Flow Management

- Inventory Management

- Asset Utilization

- A Network of Associate Consultants To Lend Assistance on Larger Assignments or Where Their Unique Skill Set Will Bring Value to the Project

Let our consulting experts help you with lean manufacturing, lean office, and lean supply chain management.

Case Study: Flange Yoke Cell

Challenge:

We were confronted with a situation where a family of eight flange yokes was chronically late for delivery. Although the plan was for a 30-day lead time, deliveries reached 45 days with extensive expediting.

Analysis:

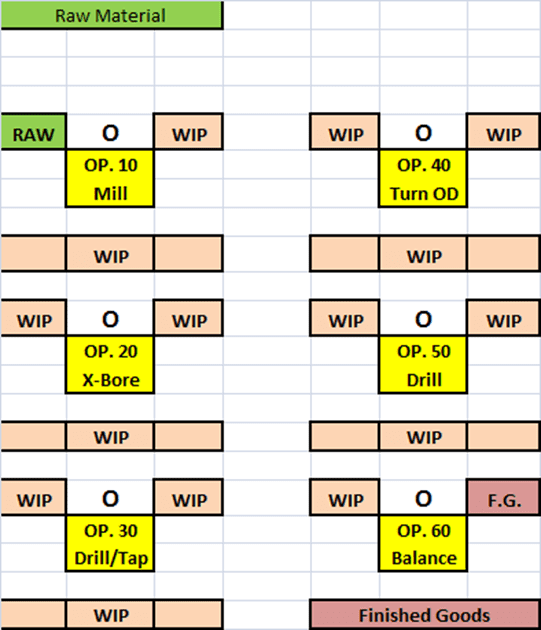

The plant was arranged with separate departments for each machine type, and the yoke was placed into the WIP inventory as it left each department prior to being scheduled to run in the next.

The family of flange yokes was then routed through all or several of the six departments (see layout). Each machine department contained multiple machines capable of performing the required task.

Proposal:

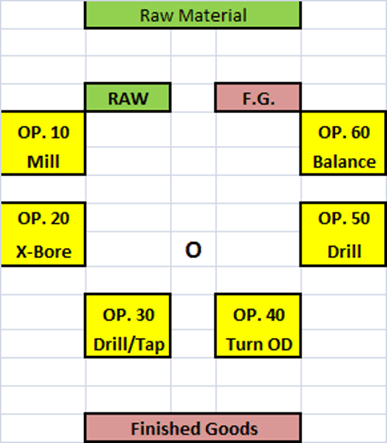

•Select one machine from each of the effected machine departments.

•Clear floor-space by removing WIP stock rack which will no longer be necessary and relocating a couple machines

•Create a manufacturing cell in a u-shaped form with the product flowing clockwise from a raw forging tub through the selected six machines to a finished parts tub. (see layout)

•Cross-train operators to setup and run all six machines.

Results:

•Free floor-space due to removal of WIP inventory rack and closer spacing of effected machines

•Only one scheduling activity for a completed yoke

•Less than four minutes of processing lead time versus previous standard of 30 days and actual of as much as 45 days

•Improved quality as the operator handles each piece and catches defects and variability as it takes place rather that after all pieces are produced

•Elimination of WIP inventory and associated stock rack

•63% less direct labor

•83% less indirect labor (fork lift operators)

•Virtually zero sort, rework and scrap

•Much shorter overall lead times with less capital tied up in raw and finished goods inventory

Lean Office: The Virtues, Myths, and Misapplications

What is Lean Office?

Lean office is an offshoot of lean manufacturing and is an element of what is now being promoted as the lean enterprise, which evaluates the entire organization.

It is a process of continuous improvement that focuses on the elimination of waste in the value stream by removing or minimizing non-value-added activities and resources.

Lean office evolved once it was discovered that the same tools and concepts that benefited the manufacturing world could do likewise in other environments:

- Non-Manufacturing Businesses

- Office Environments

- The Service Industry

Click "Here" to contact our consulting specialists at Lean System Integrators, Inc. for more information on how you can have a lean office.